Artifcial Intelligence

We Provide Multiple AI Solutions

Decision Support Tools

Chatbot Development

Predictive Analytics

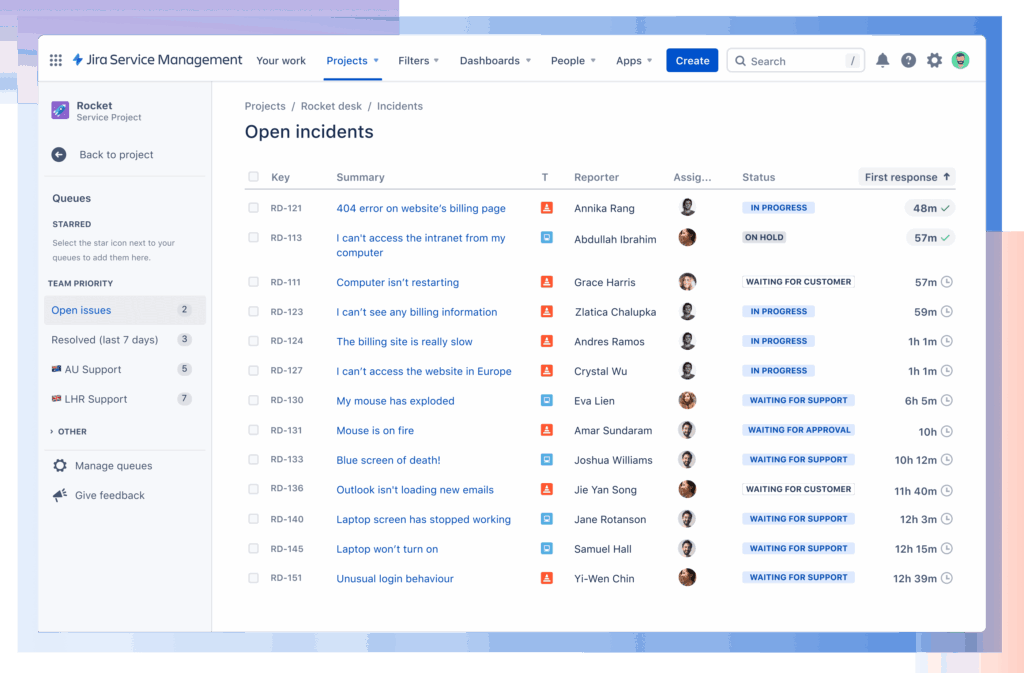

Jira Chatbot

Master1Tech has a proven track record of successful chatbot implementations, seamlessly integrating AI-powered assistants with Jira Service Management to automate up to 50% of IT support requests and boost efficiency for clients across industries, as demonstrated in deployments

Master1Tech has also delivered advanced chatbot solutions that reduce IT ticket resolution times by 25%, empowering companies with intelligent automation and seamless user experiences, as evidenced by projects finalized.

Discover

Expert Jira Service Management

Solution Provider

We Provide AI Decision Support

For Industries

How We Provide AI in Manufacturing?

Manufacturers have only begun to capitalize on artificial intelligence (AI) and machine learning capabilities on the factory floor. Today, AI’s key roles in manufacturing expand beyond robotics and automation – they now include driving overall equipment effectiveness (OEE), optimizing processes and creating a pivotal role in predictive maintenance.

Predictive Maintenance for Industrial Equipment Project

Master1Tech Using Siemens Mindsphere, AWS loT, PyTorch, IBM Maximo with Watson AI

Identify the company’s objectives, such as reducing equipment downtime by 25%, and map out data sources like sensor readings and maintenance logs to be integrated using Siemens MindSphere and AWS IoT SiteWise.

Use Siemens MindSphere to gather real-time IoT data from industrial equipment sensors and AWS IoT SiteWise to centralize and process this data into a unified format for analysis

Build machine learning models using PyTorch to analyze historical and real-time data, predicting equipment failures with 92% accuracy by identifying patterns in vibration, temperature, and wear metrics.

Implement IBM Maximo with Watson AI to incorporate the predictive models, generating automated maintenance schedules and alerts based on failure predictions and equipment health scores.

Test the system by simulating equipment scenarios to ensure accurate predictions, then deploy it across the company’s facilities, using AWS IoT SiteWise to monitor performance in real-time.

We Provide AI Decision Support

In Medicine

Designing AI Decsion Making In Medicine

Master1Tech Using Dynamics 365, Tableau, Python and Snowflake

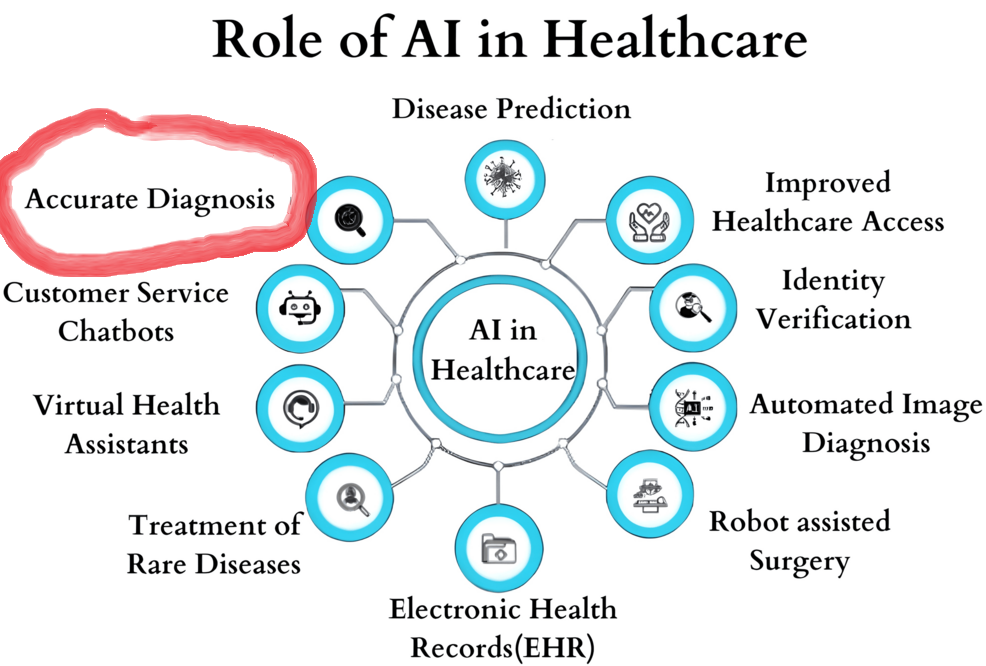

AI Projects in Healthcare: Accurate Diagnosis for Chronic Diseases

This predictive decision-making AI project focuses on developing an Accurate Diagnosis Support System for a mid to large-sized healthcare provider, aimed at improving the diagnosis of chronic diseases like diabetes and heart disease by leveraging machine learning (ML) to analyze patient data and provide clinicians with probabilistic diagnostic insights.

Establish the project’s objectives, such as improving diagnostic accuracy by 20% and optimizing resource scheduling, by identifying patient data sources like EHRs and lab results, and operational data within Microsoft Dynamics 365, using Tableau for initial data visualization.

Aggregate patient data from EHR systems like Epic Systems and operational data (e.g., clinician schedules, diagnostic equipment availability) from Microsoft Dynamics 365, cleaning it with Python using pandas and storing it securely in Snowflake for analysis.

Use TensorFlow to build predictive models, training them on patient data stored in Snowflake to provide probabilistic diagnoses for chronic diseases with 90% accuracy, leveraging Google Cloud AI Platform for model training and deployment.

-

Develop a clinician interface using Microsoft Power Apps, integrating TensorFlow models via Google Cloud AI Platform to deliver diagnostic insights, while connecting with Microsoft Dynamics 365 to schedule follow-up tests and allocate resources based on diagnostic needs.

Conduct pilot testing with clinicians and operations teams to validate diagnostic accuracy and operational efficiency, refining TensorFlow models with Google Cloud AI Platform and tracking performance metrics like scheduling accuracy using Tableau dashboards.

Predictive Analytics In Retail

AI Retail Predictive Analytics Case Studies

Cotopoxi & TensorFlow, Python Plus Tableau

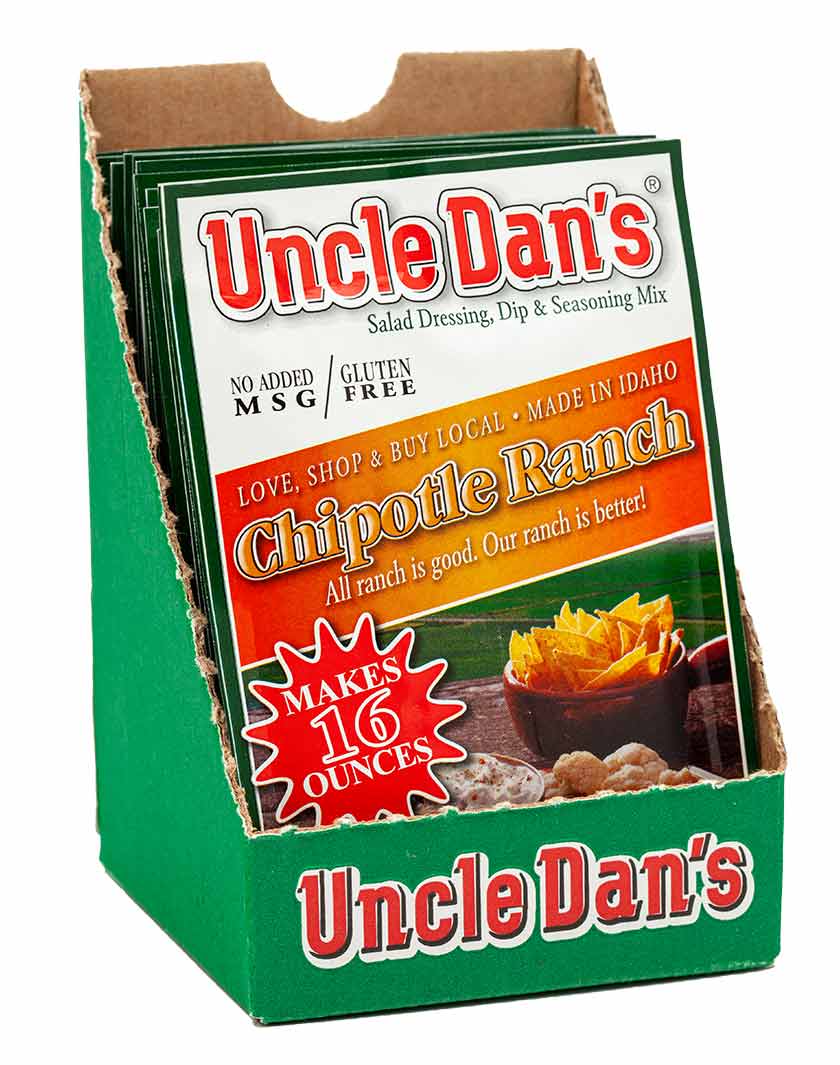

Uncle Dan's & TensorFlow, Python Plus Tableau

Designing Inventory AI Decsion Making In Retail

Master1Tech Using Netsuite, Python. Tensorflow, Mulesoft and Tableau

Identify the company’s inventory issues, such as $400K in annual stockout losses, and map out data sources like sales records in NetSuite ERP and external factors like consumer trends in Google BigQuery, using Tableau to visualize initial patterns.

Aggregate sales data from NetSuite ERP and external demand data from Google BigQuery, cleaning and standardizing it with Python using pandas to ensure consistency for metrics like seasonal product sales and regional demand.

Use TensorFlow to build predictive models in Python, training them on combined NetSuite and Google BigQuery data to forecast inventory needs with 90% accuracy, identifying risks of stockouts and overstocking for seasonal products.

Integrate the TensorFlow models with NetSuite ERP and BigCommerce using MuleSoft Anypoint Platform to enable automated reordering and dynamic pricing adjustments, ensuring real-time inventory syncing across distribution centers and the e-commerce platform.

Conduct pilot testing with the company’s operations teams to validate the system’s predictions, comparing AI forecasts against actual inventory performance and refining models with TensorFlow, while tracking stockout reductions using Tableau dashboards.

Deploy the inventory optimization system across the company’s operations, monitor its impact with Tableau to confirm a 36% stockout reduction and $280K in savings, and continuously update TensorFlow models with new data from NetSuite and Google BigQuery to maintain accuracy over time.